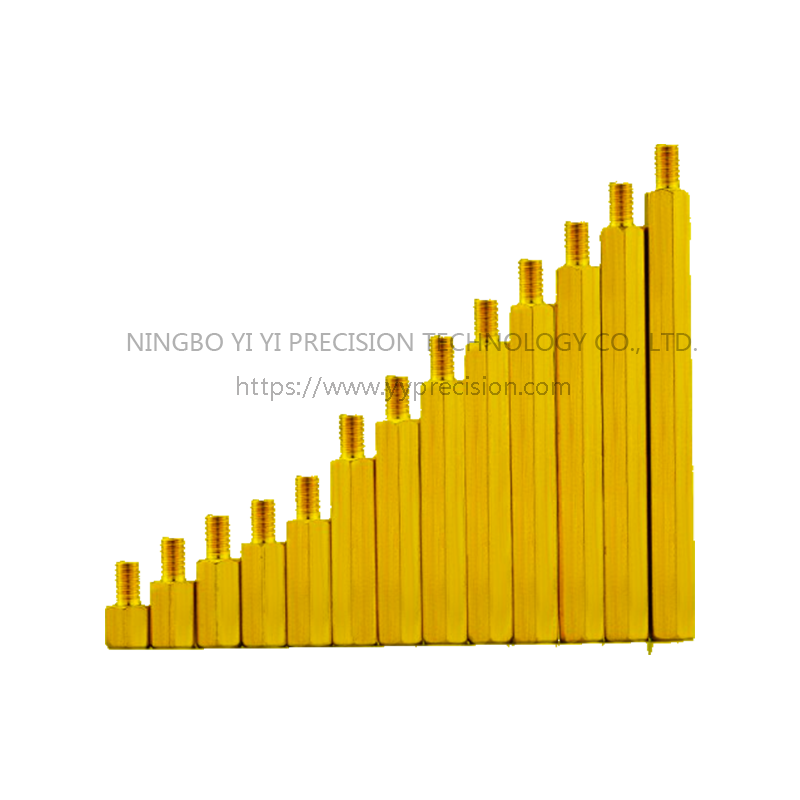

As a common mechanical connection element,

Metal Hexagonal Pillar Screws play a vital role in industrial production and daily life due to their good mechanical properties and corrosion resistance. This superior performance is due to the combined effect of many factors.

Metal hexagonal post screws are often made of high-quality metal materials such as carbon steel, stainless steel or alloy steel. These materials have excellent mechanical properties such as high strength, hardness and toughness, and can withstand various static and dynamic loads, ensuring the firmness and reliability of the connection. Among them, stainless steel has good corrosion resistance and is not easily corroded by most chemical media and environmental conditions, thereby extending the service life of the screw, and is especially suitable for applications in humid and corrosive environments.

The structural design of metal hexagonal post screws also plays an important role in its performance. The hexagonal cylindrical head design makes it more convenient to use a wrench or wrench, and can apply greater torque, enhancing the efficiency and convenience of tightening operations. In addition, the design of the thread structure is also crucial. Reasonable thread angle, height, width and other parameters can ensure a tight connection with the nut and effectively prevent loosening and falling off.

Metal hexagonal post screws are often surface treated to further improve their corrosion resistance. Surface treatment processes such as galvanizing, chromium plating, and phosphating can form a protective surface coating to effectively prevent oxidation and corrosion. These surface treatments not only provide additional protection against corrosion but also make the screws more aesthetically pleasing for use outdoors, in wet or corrosive environments.

The reason why

Metal Hexagonal Pillar Screws have good mechanical properties and corrosion resistance is the result of a combination of factors. Reasonable material selection, structural design and surface treatment can enable screws to exhibit excellent performance under various working conditions, and have a long service life and reliable connection effect, providing important support for engineering assembly and maintenance work. Assure.

CARBON STEEL SCREWS

CARBON STEEL SCREWSYin Yang Screws / Carbon Steel Series Yin Yang Screws

It Is Processed By STAR Dual-Spindle CNC Centering Machine. First, The Small Outer Diameter Of The End Face And The Hexagonal Outer Diameter Are Processed With A Cylindrical Cutter Of 55°R0.2 Corner, And Then The Turning Tool With R0.2 Corner Is Used To Rough The Outer Diameter, Then The Tungsten Steel Milling Cutter Is Used To Process The Hexagon, And Then The Cylindrical Cutter With 55°R0.2 Corner Is Used To Remove The Hexagonal Burr.