Tolerances and Dimensions:

Non-standard high precision hardware parts often require extremely tight tolerances. Precise dimensions are important for the proper functioning and integration of these parts into large systems. Design engineers have to specify the allowable versions in dimensions to make sure consistency and accuracy at some stage in production.

Material Selection:

Choosing the proper fabric is crucial for the overall performance and sturdiness of high precision hardware components. Stainless steel is a not unusual choice due to its corrosion resistance, power, and machinability. The particular grade of chrome steel should be decided on primarily based on factors which include environmental conditions, temperature, and mechanical requirements.

Surface Finish and Aesthetics:

The floor finish of Non-standard high precision hardware parts is critical for both practical and aesthetic reasons. Certain packages may also require particular finishes to beautify corrosion resistance, lessen friction, or improve the overall appearance of the additives. Consideration of floor finishes including sprucing, passivation, or coating need to be part of the layout manner.

Complex Geometries:

Some applications may additionally necessitate complex geometries that can not be performed through traditional production approaches. Designing non-general precision components regularly includes using advanced strategies consisting of CNC machining, EDM, or additive manufacturing to create complicated shapes and functions.

Functional Requirements:

Clearly defining the functional necessities of the hardware parts is critical. This includes know-how how the components will have interaction with other elements in the device, the loads they'll endure, and any particular performance criteria they must meet. Functional considerations can also have an impact on the selection of capabilities including threads, holes, or grooves.

Material Compatibility:

Compatibility with other materials in the gadget, in addition to environmental considerations, is critical. Some applications may additionally require non-fashionable hardware components to withstand chemical publicity, severe temperatures, or other harsh conditions. The design should account for material compatibility to make sure lengthy-term reliability.

Assembly and Integration:

A design that is easy to assemble and integrate into larger systems is crucial. This includes thinking about factors which includes alignment features, fastening strategies, and any unique considerations for installation. Well-thought-out designs streamline the assembly process and decrease the hazard of errors during integration.

Regulatory Compliance:

Depending on the industry and application,

non-standard precision hardware parts may additionally need to comply with specific rules and standards. Design engineers ought to be privy to applicable enterprise standards, safety necessities, and certifications to make certain the very last components meet all important compliance standards.

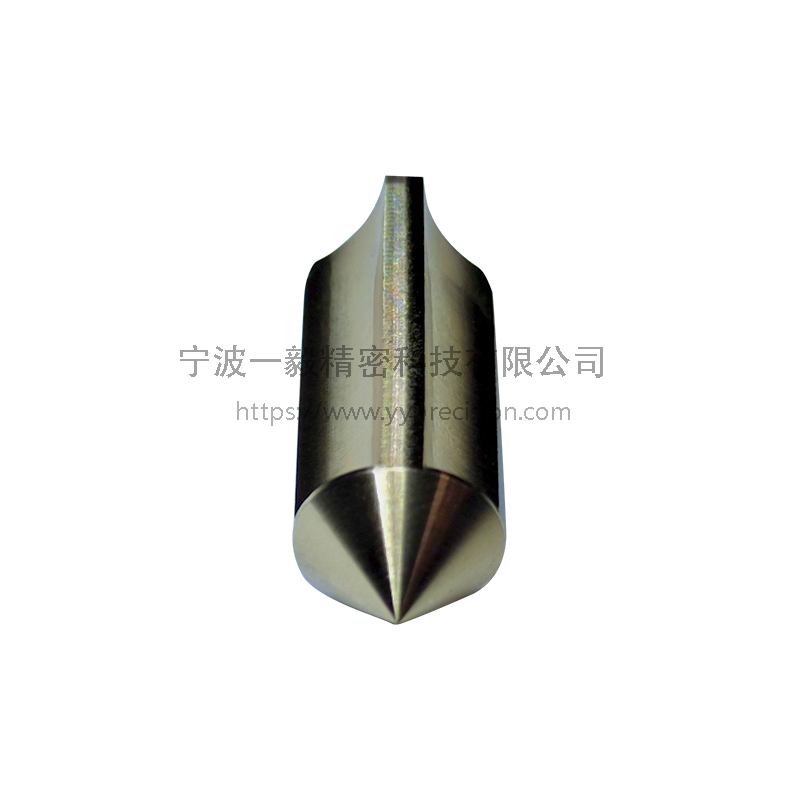

HYDRAULIC SPOOL

HYDRAULIC SPOOL

Commonly Used To Step Up And Control Lubricating Oil Circuit

Material:1.4305 (SUS303CU)

Outer Diameter:5.0mm

Length:25.0mm

Side Hole:1.0 -0.05m