Ningbo Yi Yi Precision Technology Co., Ltd.

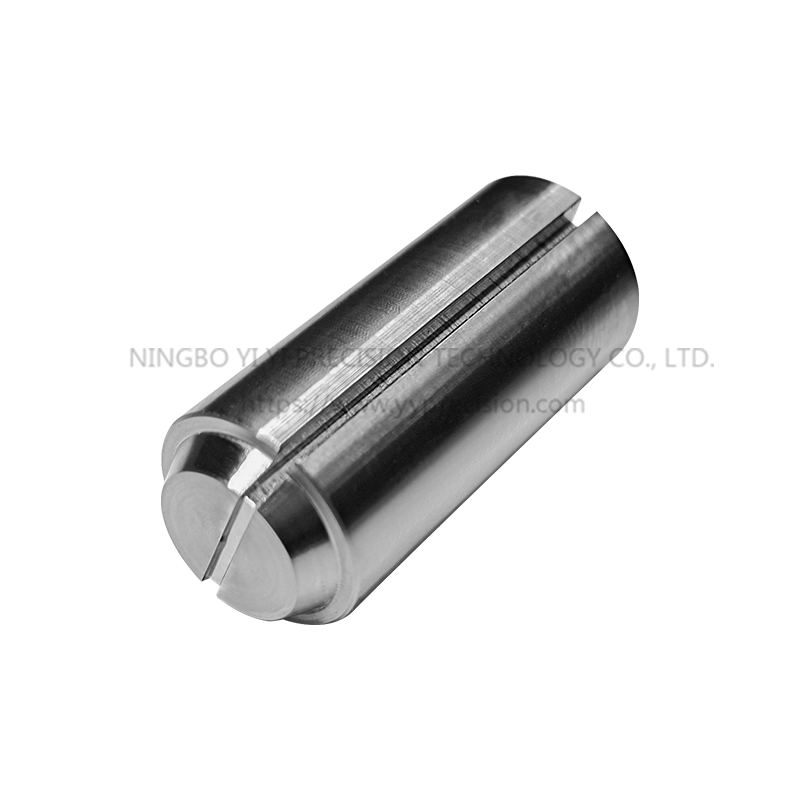

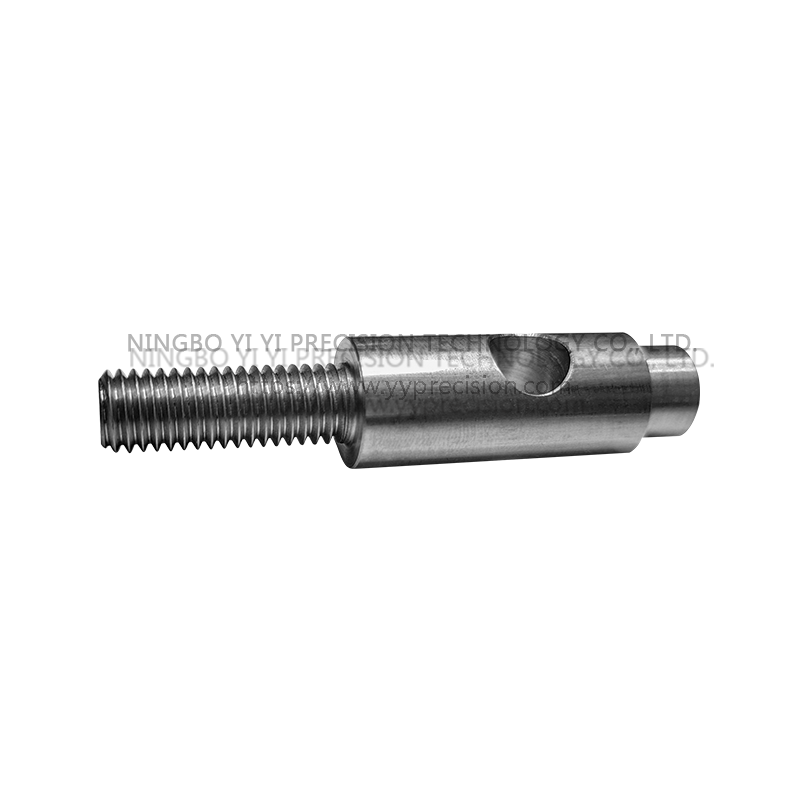

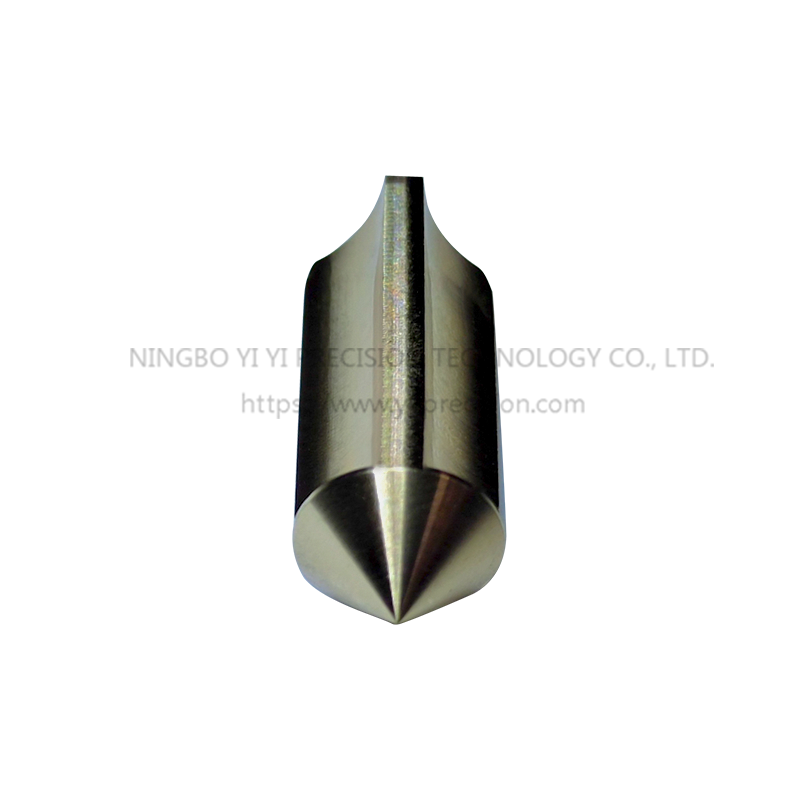

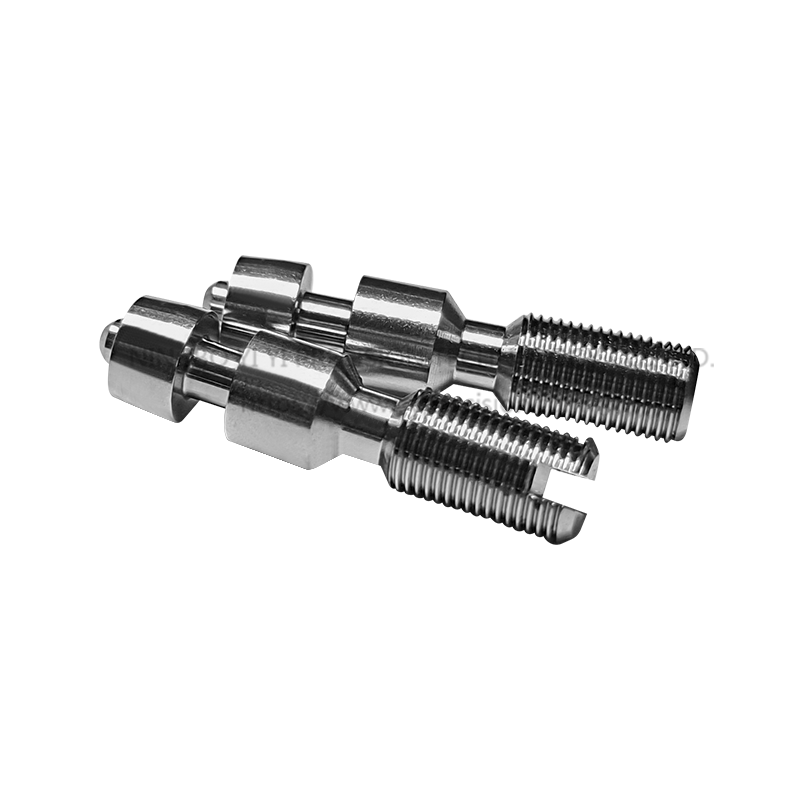

Ningbo Yi Yi Precision Technology Co., Ltd. is famous China Non-standard high precision hardware parts Manufacturers and Non-standard high precision hardware parts factory, established in 2022-04-07, is a combination of industry and trade enterprises, including Ningbo Xinhaocheng Precision Parts Co. With 1000 square meters of production plant and 30 employees. Its 2 companies focus on centering machine processing, production of wholesale Non-standard high precision hardware parts, and has advanced imported equipment from Japan: STAR and Tsugami 5-9 axis centering machine, Citizen lathe, machining center and other equipment. The machine has the function of six-axis turning processing, which can complete drilling, turning, milling, tapping, boring, reaming, hobbing, shaping, etc. at one time, which can ensure the high precision, consistency and stable tolerance of shape of the parts. And according to the customer's needs, the power cutting tool function module with front and side milling function can be installed to complete the precision machining of complex shaft parts.

EN

EN  English

English 中文简体

中文简体