The process of producing

precision die casting parts involves a number of steps. The first step is to define the surface finish desired. Surface finishes are grouped into three general categories: as-cast, superior grade, and decorative. Choosing the right surface finish depends on the end use for the part. In the case of decorative parts, the designer may use a different finishing process than that used for functional parts.

The next step is to design the part's structure. This includes taking into account the pressure and stress required for the casting process. A die should be designed to minimize the amount of stress, which will result in a more accurate part. When designing a die cavity, the designer should also consider the material's performance. It is also important to keep the structure as simple as possible. The wall thickness and the die inclination must be carefully reserved.

Parting lines can also be challenging to place. They are not as smooth as other surfaces and are exposed to intense pressure during die casting and plastic injection molding. A high-quality die is essential for minimizing the risk of parting lines. Using proper casting parameters and using a quality die will minimize this risk.

Another critical step in die casting is the secondary assembly step. In addition to threaded fasteners, die casters can also use adhesives to join die cast parts. However, it is important to remember that adhesives can dilate or crack if the materials are not compatible with each other. In addition, adhesives can be susceptible to thermal degradation and peeling.

Cast-in-place inserts are also available. The downside is that they require the same level of dimensional accuracy as the die, which adds to cycle time and cost per part. Cast-in-place inserts are generally more economical for large-scale castings, while post-installed inserts are better for smaller-scale production runs and parts with lower tolerances.

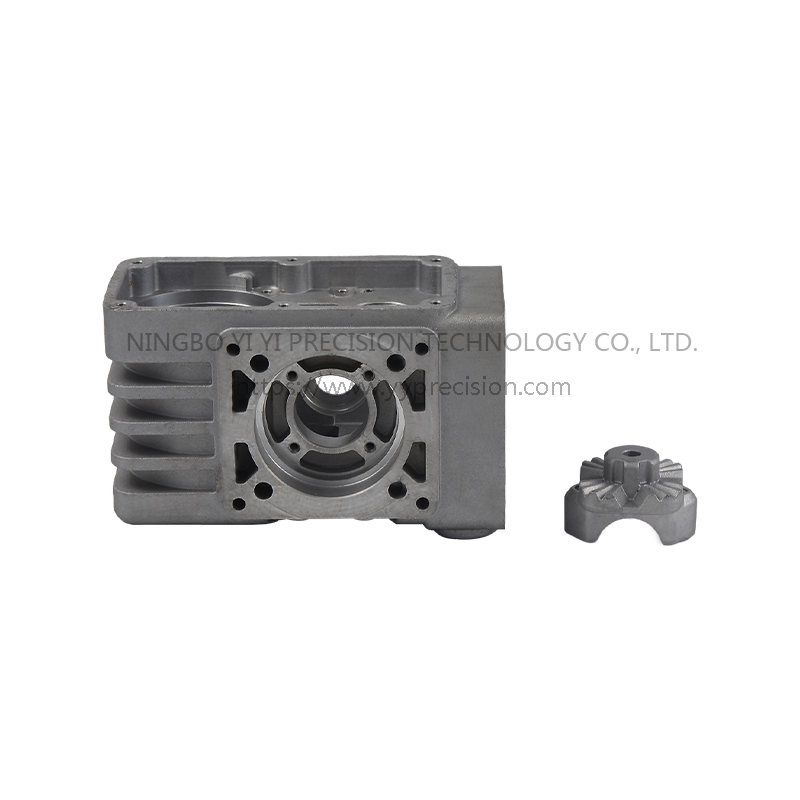

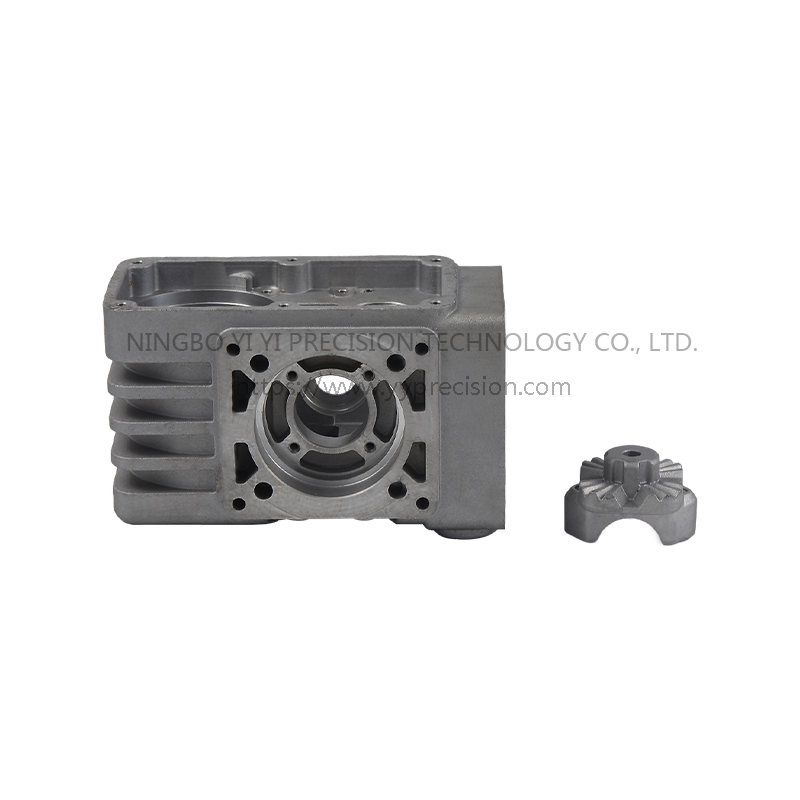

ZINC ALLOY DIE-CASTING

ZINC ALLOY DIE-CASTING

Low Cost For Manufacturing Complex Shapes Using Molds, Mainly For Low Load Applications

Material: Zinc Alloy

Weight: 2KG