Stainless Steel Crank Shaft

Material:Shaft

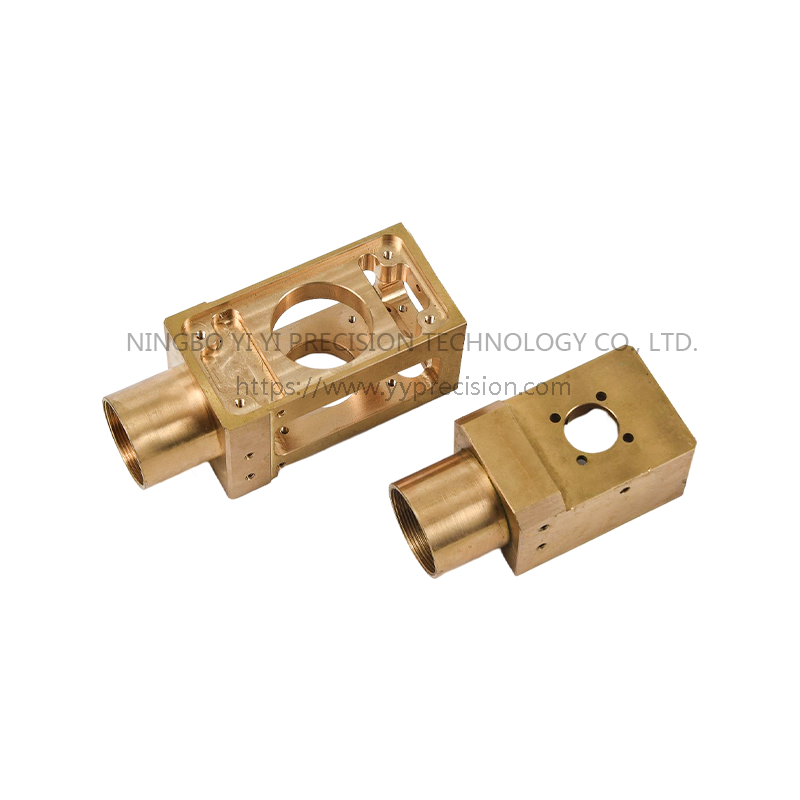

| Material: | brass | Size: | OD 60*60*146mm |

| Weight: | 305g | Color: | natural |

Ningbo Yi Yi Precision Technology Co., Ltd. is leading China CNC Motor Mount suppliers and OEM/ODM CNC Motor Mount company, a combination of industry and trade enterprises, including Ningbo Xinhaocheng Precision Parts Co. With 1000 square meters of production plant and 30 employees. Its 2 companies focus on centering machine processing, production of precision non-standard parts, and has advanced imported equipment from Japan: STAR and Tsugami 5-9 axis centering machine, Citizen lathe, machining center and other equipment. The machine has the function of six-axis turning processing, which can complete drilling, turning, milling, tapping, boring, reaming, hobbing, shaping, etc. at one time, which can ensure the high precision, consistency and stable tolerance of shape of the parts. And according to the customer's needs, the power cutting tool function module with front and side milling function can be installed to complete the precision machining of complex shaft parts.

First, pipeline connection 1. Water supply system: (1) In the household water pipeline connection, 304 stainless steel hexagonal outer wire connector can be use...

No.56 Huanghai Road, Xinqi Street, Beilun District, Ningbo, Zhejiang, China (inside Xingzhi Industrial Park)

+86-15990595543

+86-0574-86110696

Grace@YY-Precision.com