Medium carbon steel is a versatile material that is widely used in the manufacturing industry due to its superior strength and durability. Known for its high toughness and medium level of hardness, medium carbon steel is perfect for producing turned parts that can withstand heavy loads, wear and tear, and other harsh conditions.

What are Medium Carbon Steel Turned Parts?

Medium carbon steel turned parts are made by using CNC lathe machines and turning tools to shape and form metal components. These parts are used in many different industries, including automotive, aerospace, medical, and construction, to create durable and reliable products.

Why Use Medium Carbon Steel for Turned Parts?

Medium carbon steel has many benefits that make it an ideal material for producing turned parts. Firstly, it has a high level of toughness which allows it to withstand heavy loads and shocks without breaking or cracking. Additionally, it is highly resistant to wear and tear, which is important in industries where components need to last a long time.

Another advantage of medium carbon steel is its excellent machinability. It can be easily turned and shaped using standard CNC machines, which makes it an economical choice for manufacturers. Additionally, medium carbon steel can be heat treated to further increase its strength and durability.

Applications of Medium Carbon Steel Turned Parts

There are many applications for medium carbon steel turned parts across multiple industries. In the automotive industry, these parts are used to manufacture components such as shafts, gears and bearings. In the aerospace industry, they are used in critical applications such as landing gear and engine components. In the construction industry, medium carbon steel turned parts can be found in building materials such as bolts, screws, and nuts.

Advances in Turning Technology

The latest advances in turning technology have made it possible to produce even more complex and precise components using medium carbon steel turned parts. The development of advanced CNC machines and software programs has significantly increased the efficiency and accuracy of the turning process, which has led to higher quality components and reduced lead times.

In addition, the use of high-pressure coolant systems and innovative cutting tools has made the machining of medium carbon steel parts even more efficient and productive. This has allowed manufacturers to produce parts with better surface finishes, tighter tolerances, and improved dimensional accuracy.

Medium carbon steel turned parts are an essential component in many industries. The strength, durability, and machinability of medium carbon steel make it an ideal material for producing components that can withstand heavy loads, wear, and tear. With the latest advances in turning technology, the quality and precision of medium carbon steel turned parts have improved significantly, making them an even more attractive option for manufacturers.

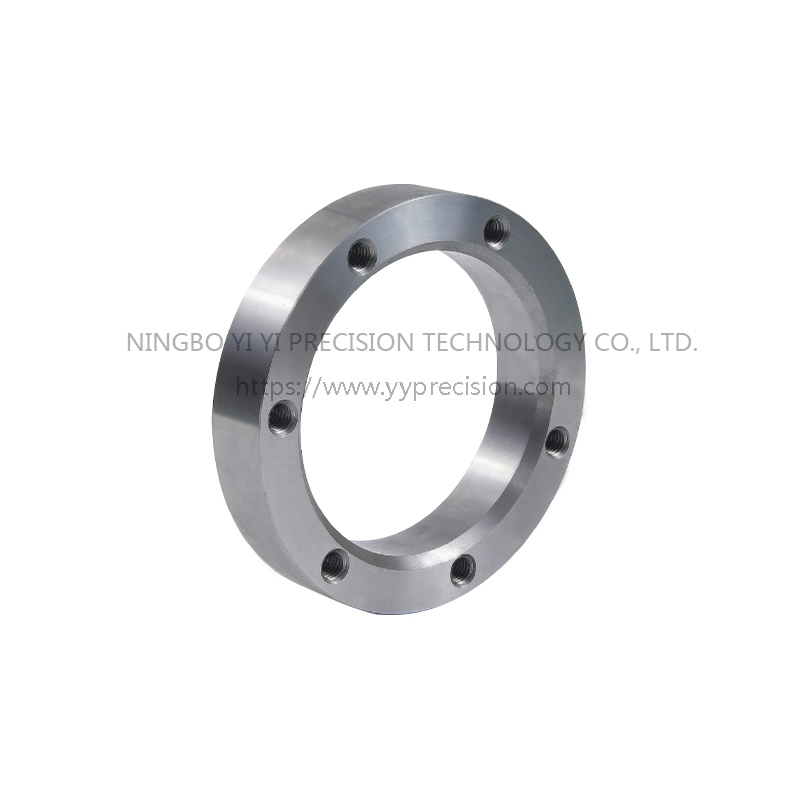

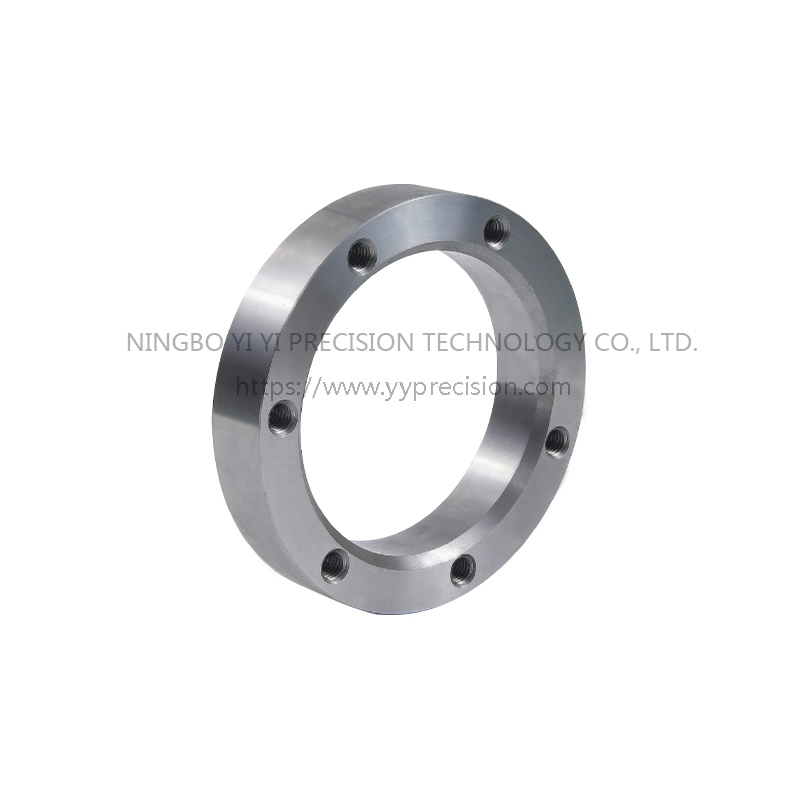

Medium Carbon Steel Turned Parts With Threaded End Holes

CNC Lathe Processing. First, Use A U Drill To Make Holes, Then Use A Tungsten-Carbide Boring Cutter With R0.4 Corner To Drill Internal Holes, Then Use A Tungsten-Carbide Boring Cutter With R0.2 Corner To Finish Internal Holes, Then Use A Cylindrical Cutter With 55°R0.2 Corner To Process The End Face And The Outer Diameter, Finally Cut Off, And Then Use CNC Machining Center, A Flat Cutter To Process The Plane, A D5.0 * 90° Center Drill To Center, A Tungsten-Carbide Twist Drill To Process The M2.5 Thread Bottom Hole, And M2.5 Tapping To Process The Thread, Then Change The End Of The Product To Continue Processing.

Double-Sided Misaligned Threaded Holes With A Flatness Of 0.05 Or Less Are Available For Use In Pumps And Valves.The Flange Connection Is Easy To Use And Can Withstand Large Pressure. Flange Connection Is Widely Used In Industrial Pipelines. In The Family, The Pipe Diameter Is Small And At Low Pressure, And Flange Connections Are Not Visible. If In A Boiler Room Or Production Site, There Are Flange Connections Everywhere For Pipes And Equipment. According To The Connection Method Flange Connection Types Can Be Divided Into: PL, SO, WN, SW, Th, BL, PJ/PE, PJ/JR...

Material: 45#

End Thread: M2.5

Size: OD 100mm*Thickness 25mm

Weight: 350g

Thread Size: M5

Color: Natural