Precision Die Casting Parts, as a highly advanced metal processing technology, plays a vital role in today's modern manufacturing industry. It not only has outstanding advantages in product design and manufacturing, but also plays an irreplaceable role in improving production efficiency, ensuring product quality and promoting industrial upgrading.

With the continuous advancement of science and technology and the intensification of market competition, product design requirements are becoming more and more complex, and the accuracy and complexity of parts are also increasing. Precision die castings provide product designers with more possibilities by virtue of their ability to manufacture high-precision, high-complexity parts. Through precision die-casting technology, designers can achieve more complex and precise parts design, thereby promoting innovation and differentiated competition in product design and meeting the diverse needs of the market.

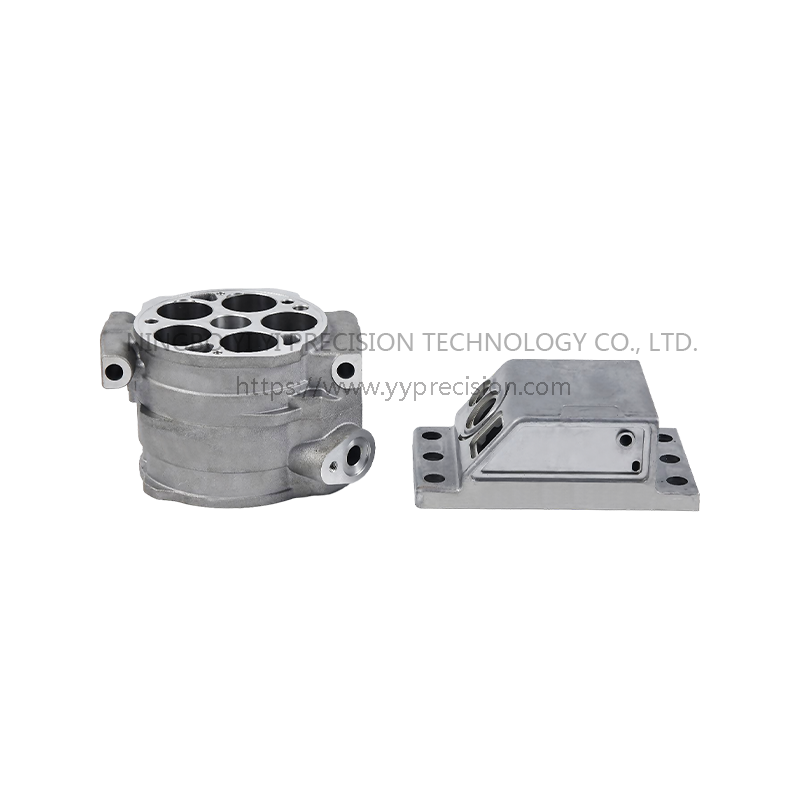

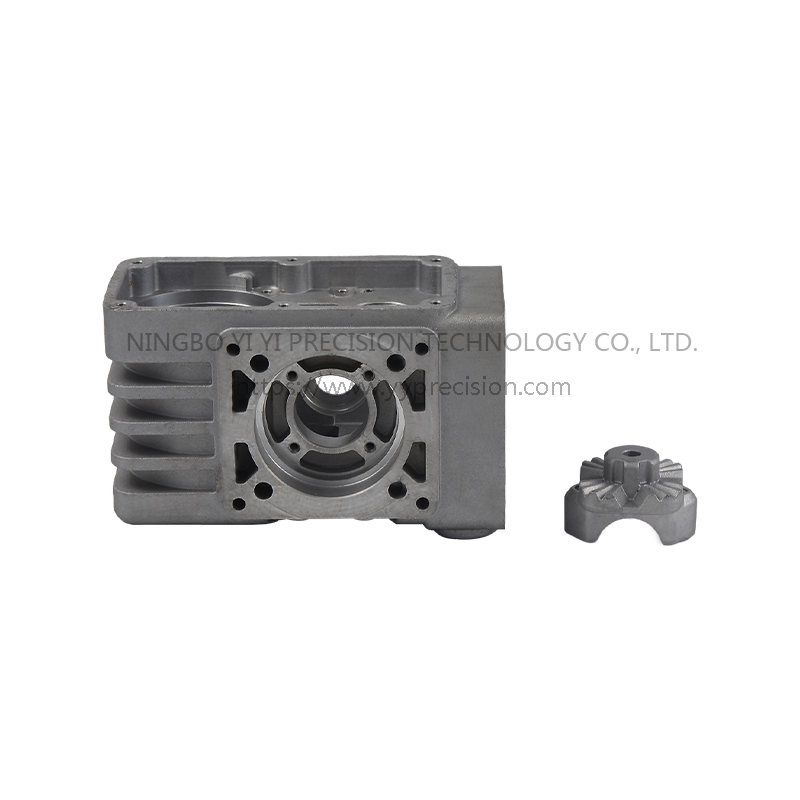

Precision die castings have obvious advantages in production technology. Compared with traditional casting processes, precision die-casting technology can quickly and efficiently manufacture complex parts through mold design and high-pressure injection. This not only improves production efficiency and shortens the production cycle, but also reduces production costs and brings considerable economic benefits to the enterprise. At the same time, the production process of precision die castings can achieve a high degree of filling and rapid cooling of materials, ensuring product uniformity and stability, and further improving product quality.

Precision die castings also have obvious advantages in product quality and performance. Due to the characteristics of good material fluidity and rapid cooling during the manufacturing process, high-density and uniform material organization can be achieved, thus ensuring the high strength, high hardness and other excellent properties of the product. Compared with traditional casting methods, precision die castings can better control the dimensional accuracy and surface quality of the product, greatly improving the overall quality level of the product.

Precision Die Casting Parts are increasingly used in modern manufacturing industries. Whether it is in the fields of automobiles, aerospace, electronics, communications or medical equipment, you can see its presence. They are widely used in manufacturing various key components, such as automobile engine cylinder heads, aircraft engine blades, mobile phone casings, etc. These parts not only play an important role in product performance and quality, but also directly affect the development and competitiveness of the entire industry.

ZINC ALLOY DIE-CASTING

ZINC ALLOY DIE-CASTINGThe Raw Material Aluminum Ingot Is Transformed Into Liquid After High Temperature Treatment, And Then Formed After Die Casting, And Then Processed.

1. Aluminum Alloy Has Good Thermal Conductivity, Electrical Conductivity And Cutting Performance; 2. Aluminum Alloy Has Small Linear Shrinkage, So It Has Good Filling Performance;