A

precision metal stamping process can reduce labor costs and increase productivity by eliminating manual handling. Small simple stamping parts can have a daily output of up to 150000pcs, while complex stamping parts can have an output of 60000-80000pcs. The process also reduces the need for tool replacement. With higher productivity, precision metal stamping can replace CNC turning and reduce machining costs by as much as 90%.

Precision metal stamping is the preferred method of manufacturing complex products, especially when high volume production is required. It's quick and efficient, and can be customized according to the exact specifications you require. Because precision metal stamping parts are produced to exact specifications, accuracy and quality are critical. Any deviation from the specifications can significantly impact the strength and functionality of the final product.

Precision metal stamping is a cost-efficient way to create parts that are exact and precise to within millimeter tolerances. Using specialized tooling, this process produces large quantities of precision metal parts at high production rates. Its applications span almost every industry. Many of the parts we use every day come from precision metal stamping. Cell phones, for example, are made of tiny stamped metal contacts. Even the structural elements of cars are made from precision metal stamped parts.

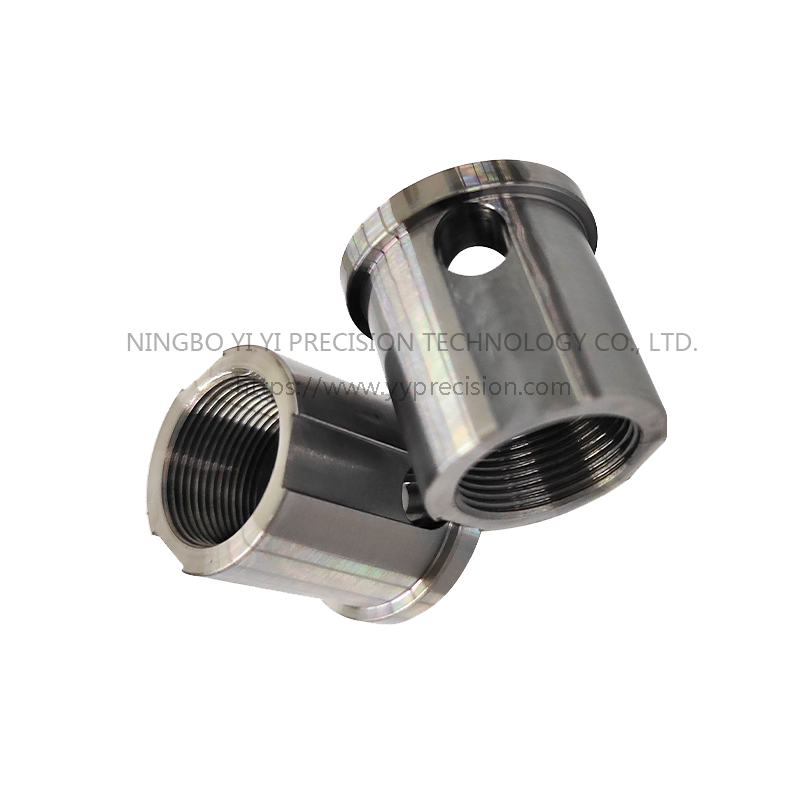

Yin Yang Screws / Carbon Steel Series Yin Yang Screws

Double-Through Type Hexagonal Yin-Yang Screws (Carbon Steel Zinc Plated).

Through-Hole Type Carbon Steel Yin-Yang Screws With Surface Treatment (Zinc Plated, Nickel Plated, New Nickel Alloy Plated, Or Blackened)

Material: Carbon Steel, Free Cutting Steel Screw Specifications Are Mainly M2, M3, M4, M5, M6, M8, M10, Etc., The Hexagonal Column Were 4.75, 5, 6, 8, 10, 12, 15mm, Etc., Which Should Be The Most Or M3 Series