Non-standard high-precision hardware parts can benefit a wide range of industries and sectors where precise, customized components are essential for performance, safety, and innovation. Some of the industries that benefit the most from these parts include:

Aerospace and Aviation: The aerospace industry relies heavily on high-precision components to ensure the safety and reliability of aircraft and spacecraft. Customized parts are used in engines, landing gear, avionics, and structural components to meet rigorous standards and reduce weight while maintaining strength.

Medical Devices: Medical equipment and devices often require non-standard, high-precision parts to ensure accuracy, reliability, and patient safety. Examples include surgical instruments, implants, and diagnostic equipment.

Automotive: The automotive industry uses custom high-precision parts in engines, transmissions, suspension systems, and safety features to improve fuel efficiency, reduce emissions, and enhance vehicle performance.

Defense and Military: Military applications demand specialized, precise components for weapons systems, vehicles, communications, and surveillance equipment to meet strict operational requirements and ensure national security.

Oil and Gas: Exploration and drilling equipment in the oil and gas industry require custom high-precision parts to withstand extreme conditions, maintain operational integrity, and ensure safety in challenging environments.

Energy and Power Generation: Power plants, including nuclear, hydroelectric, and fossil fuel facilities, utilize non-standard high-precision parts in turbines, generators, and control systems to improve efficiency and reliability.

Semiconductor Manufacturing: The semiconductor industry relies on ultra-precise components for the manufacturing of microchips and electronic components, where even tiny deviations can impact functionality.

Research and Scientific Instruments: Scientific research often requires unique, high-precision components for laboratory instruments, telescopes, and experimental setups to achieve precise measurements and discoveries.

Space Exploration: Space exploration missions, including robotic spacecraft and satellites, rely on customized, high-precision hardware parts to function accurately in the harsh conditions of space.

Telecommunications: Telecommunication equipment, such as antennas, satellite systems, and fiber-optic components, benefits from non-standard, high-precision parts to ensure signal quality and reliability.

Automated Manufacturing: Industries employing robotics and automated manufacturing systems often require specialized precision components to maintain accuracy and efficiency in their production processes.

Consumer Electronics: High-end consumer electronics, including smartphones, cameras, and audio equipment, utilize customized high-precision parts to enhance product performance and aesthetics.

Biotechnology: Customized high-precision components are essential in biotechnology applications for tasks such as DNA sequencing, gene editing, and high-throughput screening.

Renewable Energy: Solar panels, wind turbines, and other renewable energy systems benefit from precision components to maximize energy capture and efficiency.

Custom Machinery and Equipment: In various manufacturing sectors, custom machinery and equipment rely on high-precision parts to achieve specific tasks efficiently and accurately.

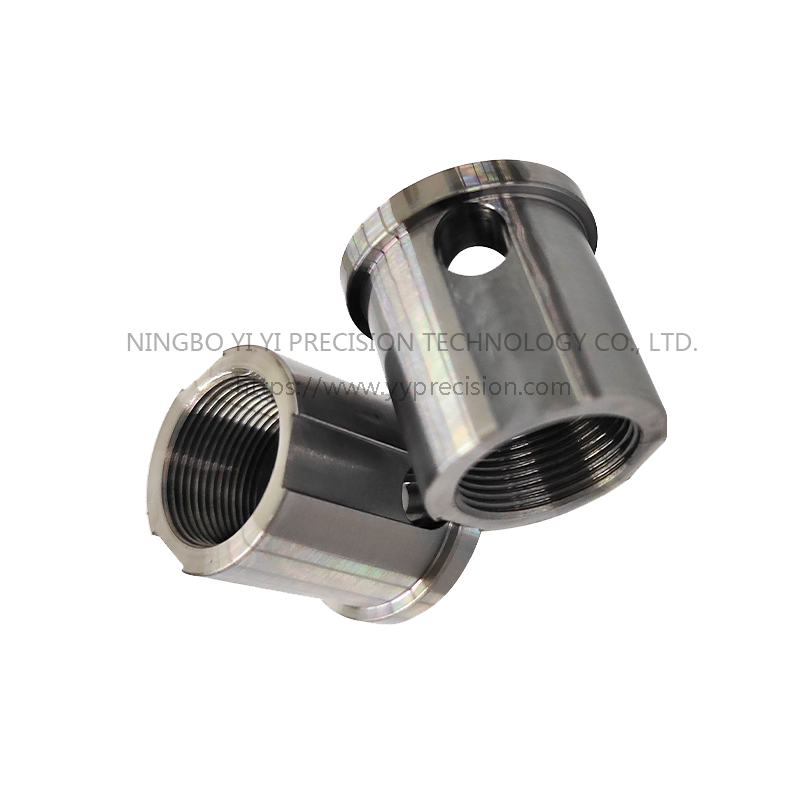

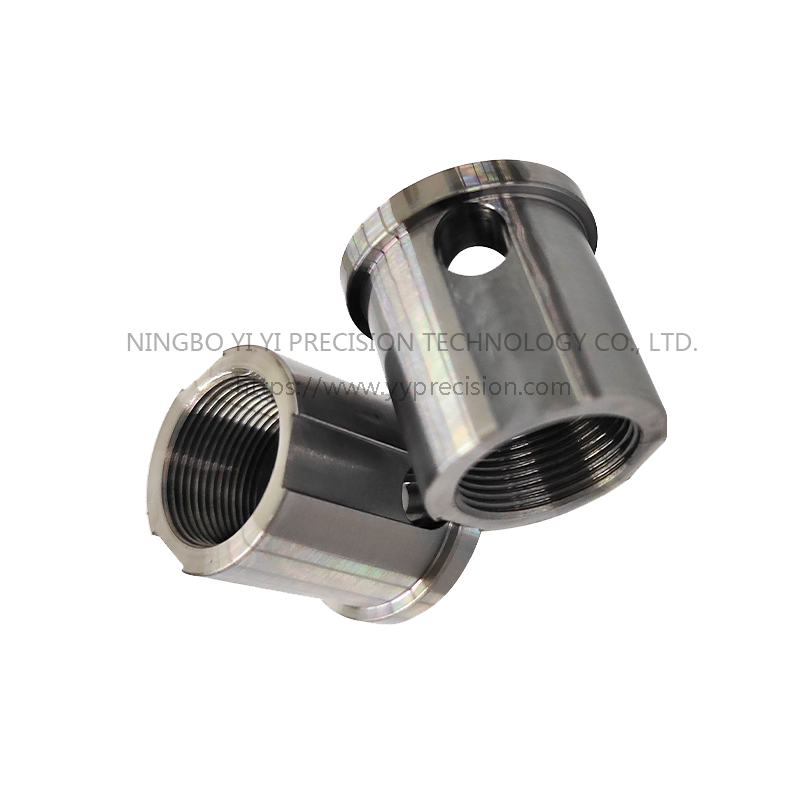

Material:1215

Size:Od 22*Length 20.6

Weight:12g

Thread Size:9/16-32UNS

Color:Galvanized