Stainless steel turning parts play a crucial role in numerous industries, ranging from aerospace and automotive to medical and manufacturing. These versatile components provide the foundation for the flawless precision required in critical applications. However, the process of turning stainless steel can often seem mysterious and complex.

Stainless steel, known for its exceptional strength, corrosion resistance, and aesthetic appeal, is a popular choice for a wide range of applications. Turning, one of the fundamental machining processes, involves the removal of material from a workpiece to create the desired shape or form. It is an intricate process that requires expertise, advanced machinery, and an in-depth understanding of the material properties.

One of the primary considerations when turning stainless steel is the choice of cutting tools. Due to the material's high strength and hardness, cutting tools must be specifically designed to withstand the demands of the process. Carbide inserts are commonly used in stainless steel turning, as they offer excellent wear resistance and toughness. Additionally, the geometry of the cutting tools, such as the rake angle and relief angle, must be carefully selected to ensure optimal chip control and minimize tool wear.

The selection of cutting parameters is another critical factor in achieving flawless precision in stainless steel turning. Factors such as cutting speed, feed rate, and depth of cut must be carefully optimized to strike the right balance between material removal and surface finish. Cutting too aggressively can lead to excessive heat generation and tool wear, while cutting too conservatively can result in poor productivity and surface quality. Achieving the ideal cutting parameters requires a deep understanding of the material and the capabilities of the turning machine.

Another challenge in turning stainless steel is the generation of heat during the process. Stainless steel has poor thermal conductivity compared to other materials, making heat dissipation a critical concern. Excessive heat can lead to workpiece deformation, tool wear, and surface integrity issues. To combat this, various techniques can be employed, including the use of coolants or lubricants to reduce friction and dissipate heat effectively. Additionally, optimizing the cutting parameters mentioned earlier can help manage heat generation and control the machining temperature.

Precision in stainless steel turning is not limited to dimensional accuracy but also encompasses surface finish and overall quality. Achieving the desired surface finish requires a combination of proper tool selection, optimized cutting parameters, and effective chip control. The material's work-hardening tendency must also be considered, as stainless steel can become harder and more difficult to machine as the process progresses. Therefore, employing suitable machining strategies and tool paths can help mitigate work hardening and maintain the desired surface finish.

Furthermore, the use of advanced turning machines equipped with state-of-the-art technology can greatly enhance the precision and efficiency of stainless steel turning. Computer Numerical Control (CNC) machines with multi-axis capabilities, high spindle speeds, and precision tooling enable intricate and complex operations with utmost accuracy. These machines, coupled with advanced software and monitoring systems, allow for real-time adjustments and ensure consistent quality throughout the production process.

In conclusion,

stainless steel turning parts are integral to achieving flawless precision in a wide range of industries. While the process may seem complex, a combination of expertise, proper tool selection, optimized cutting parameters, heat management techniques, and advanced turning machines can demystify stainless steel turning and ensure the highest quality results. By understanding the key factors and employing the right techniques, manufacturers can unlock the full potential of stainless steel turning and meet the demands of precision-driven applications.

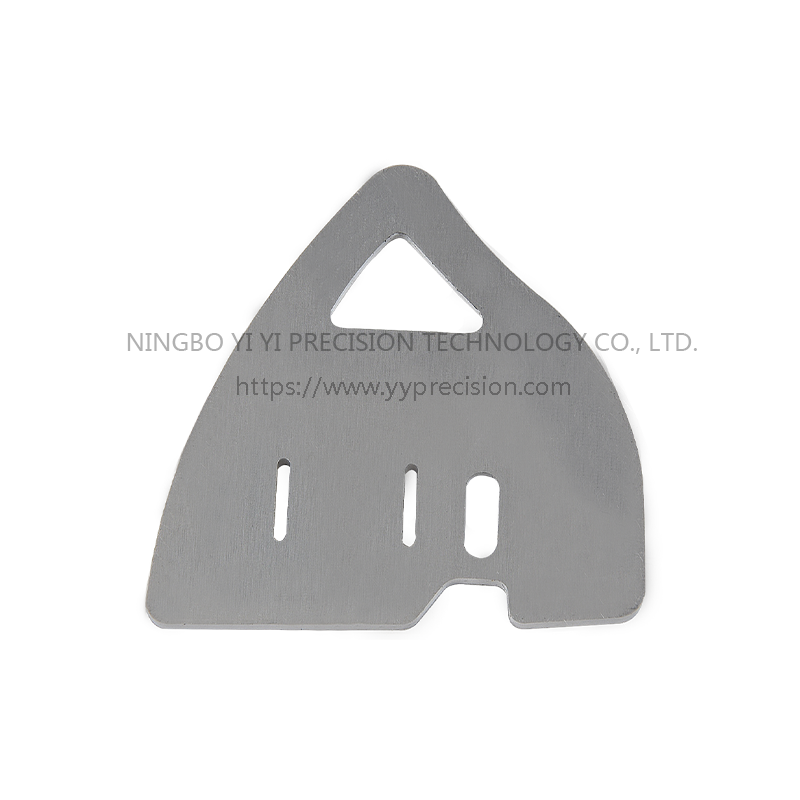

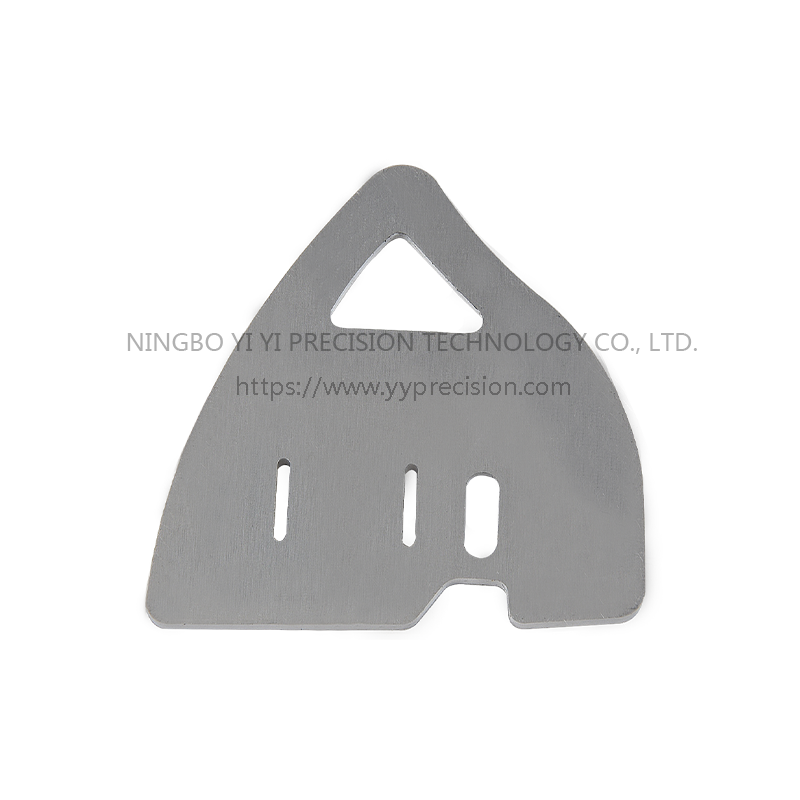

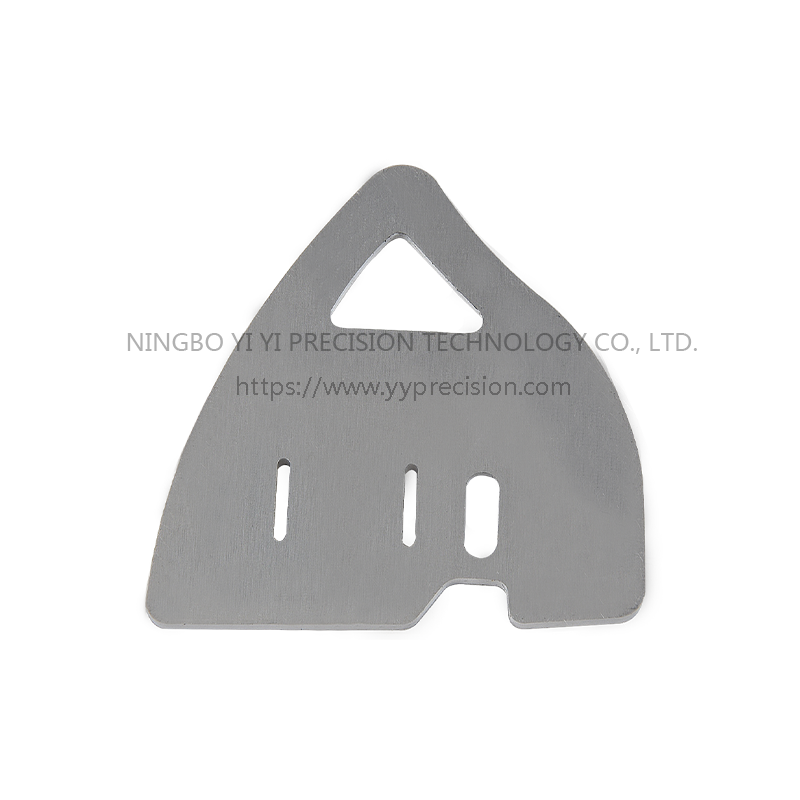

CNC Fishing Gear Cover

Purchase The Board, Make The Shape Directly On CNC, And Punch The Holes

Material: 6061

Size: (Fish Shape)

Weight: 66g

Color: Natural Color