In the world of manufacturing and engineering, the choice of materials and components can make a significant difference in the outcome of a project. One such material that stands out for its exceptional properties and versatility is stainless steel. When it comes to turning parts, stainless steel has the power to elevate ordinary projects to extraordinary levels. In this article, we will explore how stainless steel turning parts can transform your projects, revolutionizing the way you approach manufacturing and engineering.

Enhanced Durability and Strength:

Stainless steel turning parts offer unparalleled durability and strength, making them ideal for demanding applications. Unlike other materials, stainless steel exhibits exceptional resistance to corrosion, ensuring that your projects can withstand harsh environments and the test of time. Whether you're working on automotive components, industrial machinery, or precision instruments,

stainless steel turning parts provide the necessary strength and reliability.

Flawless Precision and Tolerance:

Precision is paramount in manufacturing, and stainless steel turning parts excel in this regard. With advanced machining techniques and cutting-edge technology, stainless steel turning parts offer remarkable precision and tight tolerance levels. This precision allows for intricate designs and complex geometries, enabling you to achieve the highest level of accuracy in your projects.

Versatility Across Industries:

Stainless steel turning parts find their application across a wide range of industries. From aerospace and defense to medical and electronics, stainless steel turning parts prove their versatility time and again. Whether you require components for critical aircraft parts or intricate medical devices, stainless steel turning parts can adapt to various requirements, ensuring optimal performance and functionality.

Heat and Chemical Resistance:

Certain projects demand components that can withstand extreme temperatures and corrosive environments. Stainless steel turning parts exhibit exceptional resistance to heat and chemicals, making them a reliable choice for such applications. Whether exposed to high temperatures or aggressive chemicals, stainless steel turning parts retain their integrity, ensuring consistent performance and safety.

Cost-Effectiveness and Longevity:

Investing in stainless steel turning parts not only elevates the quality of your projects but also proves to be cost-effective in the long run. The durability and resistance to wear and tear of stainless steel ensure that your components have a longer lifespan, reducing the need for frequent replacements. Moreover, stainless steel's low maintenance requirements further contribute to overall cost savings.

From durability and precision to versatility and aesthetic appeal, stainless steel turning parts have the ability to transform ordinary projects into extraordinary ones. The unique combination of strength, resistance, and versatility makes stainless steel a preferred choice for industries worldwide. By harnessing the power of stainless steel turning parts, you can take your manufacturing and engineering endeavors to new heights, achieving exceptional quality, performance, and longevity. Embrace the extraordinary potential of stainless steel turning parts and unlock a world of possibilities for your projects.

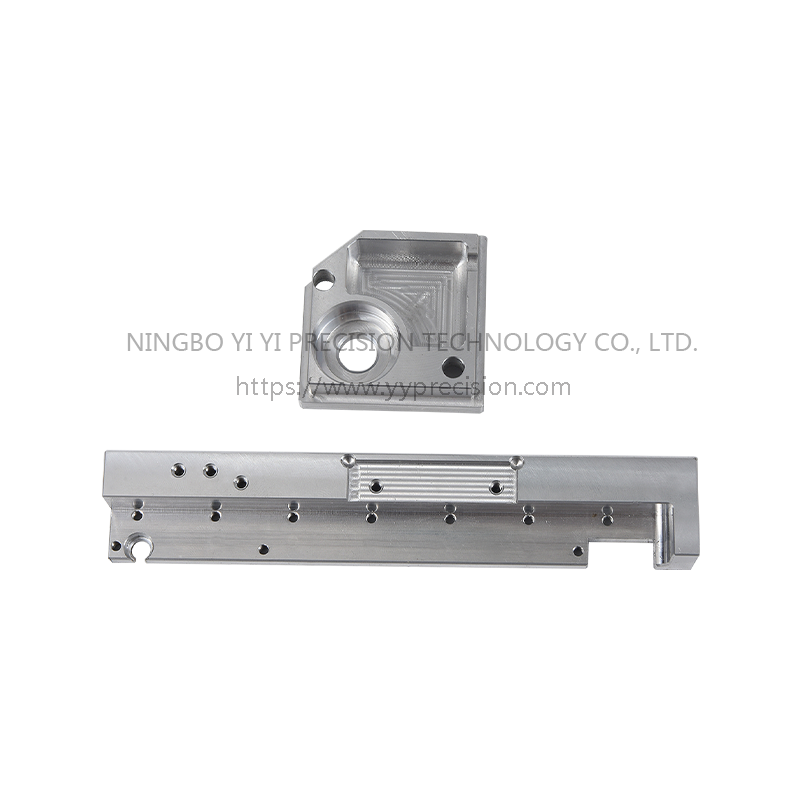

CNC Machining Of Motor Covers For Assembly Parts In The Automotive Industry

15 Threaded Holes In One Go On CNC Machine

Material: 7075

Length: 185mm

Color: Natural

Outer Diameter: 45mm

Thickness: 25mm