1. The spindle can turn parts with a length of more than 200mm in one clamping without stopping. If a part with a length of 5mm is turned, the cutting machine and

swiss turning machine can be ok. However, the swiss turning machine can produce 20~30 parts in one go before it needs to stop and feed.

2. When the machine is cutting, it is always fixed in a very close position to the turning material, so the rigidity is very good.

3. The swiss turning machine is a combination of turning and milling, and the complexity of one-time processing and forming is not comparable to that of the cutting machine. And now the updated CNC automatic lathe, we call it a center lathe or a slitting lathe. Mainly, the spindle Z moves forward and backward, and the knife can move X and Y, which can realize three-dimensional processing, and the precision parts of the machine can be processed at one time.

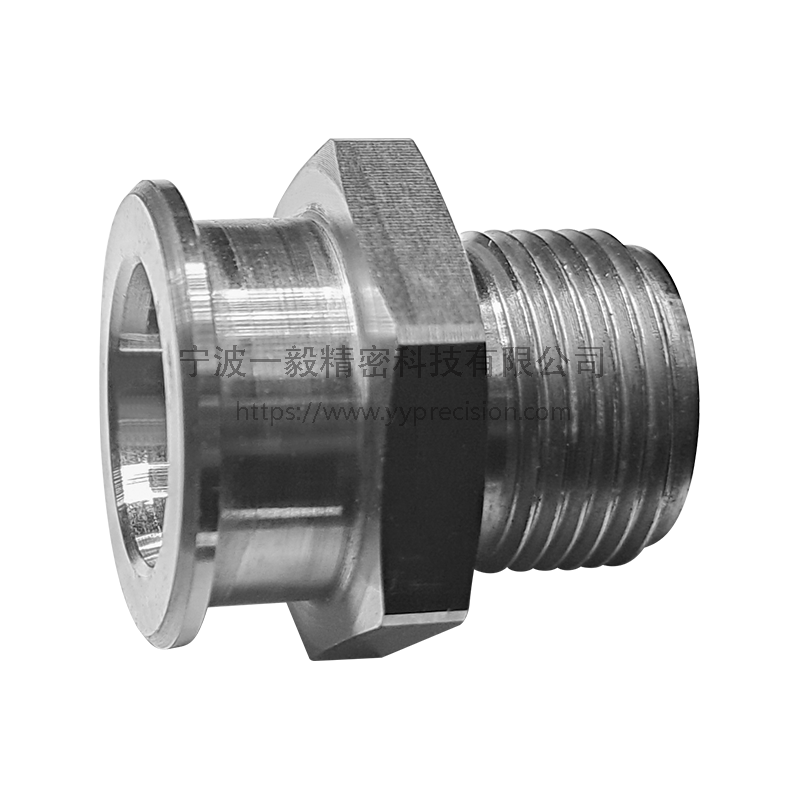

Ningbo Yi Yi Precision Technology Co., Ltd. can produce all kinds of non-standard precision turned parts, hexagonal pillar screw, pogopin linker,

stainless steel fasteners, bolt/nut cold heading parts,shaft, lock accessories/cylinder etc. according to your requirements.