Metal stamping parts are products after a series of processes, and have different names in different processes.

1. Deep drawing: a stamping process in which straight wool o r process parts are changed into hollow parts, or the hollow parts are further changed in shape and size. During deep drawing, the hollow part is mainly formed by the flow of material outside the bottom of the punch into the die.

2. Trimming: a stamping process that uses a metal stamping die to trim the edge of the forming process to make it have a certain diameter, a certain height or a certain shape.

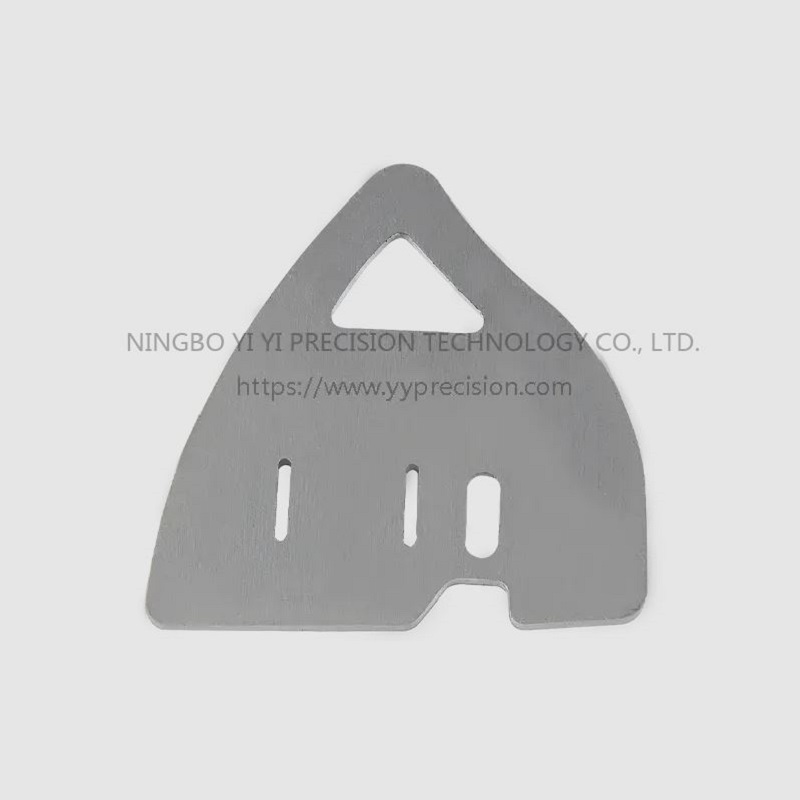

3. Punching: A punching process that separates the waste material from the material or process piece along the closed contour, and obtains the required hole in the material or workpiece.

4. Flanging:a stamping process in which the sides are turned into short sides along the contour curve.

5. Flip hole: a stamping process in which the material is turned into a side vertical flang e along the circumference of the inner hole.

6. Blanking: a stamping process that separates materials along a closed contour. The separated materials become workpieces or process parts, most of whi ch are flat.

7. Shaping: a stamping process that relies on the flow of materials to change the shape and size of the process parts in a small amount to ensure the accuracy of the workpiece.

Ningbo Yi Yi Precision Technology Co., Ltd. can produce all kinds of non-standard precision turned parts, hexagonal pillar screw, pogopin linker,

bolt/nut cold heading parts,shaft, lock accessories/cylinder etc. according to your requirements.